Xylem SAM PRO

Smart Asset Management for Performance and Reliability Optimization (SAM PRO)

Introducing a new way to optimize the performance of your asset, predict and avoid failures months before they happen.

A real-time asset condition monitoring solution for industrial rotating equipment such as pumps, mixers, and AC Motors.

How does SAM PRO work?

SAM PRO uses smart condition monitoring with predictive insights

This prevents unplanned stoppages, avoids unnecessary downtime and costs, and enables maintenance to take place only when it is needed.

This improves your life-cycle cost (LCC) and overall equipment effectiveness (OEE).

For more information or a live demo

Reduce Energy Consumption

- Minimize energy use with high-value technical and operational condition information

- Increase machine efficiency based on power supply disturbance information and patented signature analysis

- Improve process efficiency by precisely correlating technical machine condition with the process conditions

Increase Asset Lifetime

- Improve total productive maintenance (TPM) through benchmarking and diagnostic insights

- Limit repair costs and process disruption by diagnosing failures before they happen

- Streamline maintenance and inspection processes with reliable data viewable on-demand, not requiring constant monitoring

Enhance Productivity

- Increase manufacturing productivity with an operational map informed by highly consistent processed data, derived from multiple sources

- Reduce downtime through product data management (PDM) and data-driven operations

- Avoid quality deterioration with built-in machine-learning algorithms

Ready for a demo?

Technical Overview

SAM PRO Technical Overview

SAM PRO combines measurements of voltage and current from electric-motor power lines taking into account important parameters, like pressure and temperature, to create actionable insights enabled by intelligent software.

The SAM PRO algorithm can detect discrepancies long before they could be flagged by operators or performance indicators, even pinpointing the exact location and element driving the alerts, allowing you to make crucial decisions - earlier.

SAM PRO Features

What will you love about SAM PRO?

- 24/7 access to online data and reporting platform

- Integration with existing SCADA and PLC systems

- Just 30 minutes to install

- Ready-to-use machine software

Applications

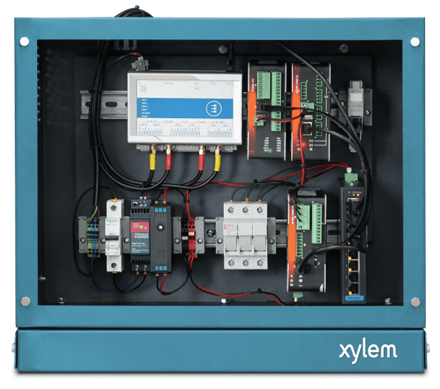

SAM PRO machine-monitoring modules are designed to be able to be installed directly in the machine-motor control panel.

If space is limited, the modules can also be provided in a commissioned, pre-wired micro panel for rapid site deployment.

Predictive Diagnostics

- Calculate machine KPIs based on high-frequency measurements of electric parameters and correlate them with key process parameters.

- Pinpoint electrical and mechanical discrepancies months before they lead to system failures.

Real-Time Monitoring

- Digitally monitor the performance of machines in real-time through integrated hardware and software.

- Intuitive and seamless user experience delivered by packaged IoT-sensors, ML algorithms and online dashboards.

Optimization

- Provide immediate information and smart alerts for predictive maintenance through automated machine diagnostics.

- Improve operations and energy efficiency.

Summary

SAM PRO provides performance insights for both mechanical and electrical systems.

It delivers a better return on capital invested and drastically reduces business risks through sophisticated software that monitors asset operations, allowing for perfectly timed maintenance and predicts future failures to eliminate unplanned stoppages. The system also collects data that can be used to design the most profitable long-term plan for asset usage, giving you optimal machine, energy and process efficiency.

SAM PRO works with any make or model of asset. For applications where deploying sensors is difficult or inconvenient, such as high-voltage, high-flow and/or low-pressure submersible pumps, SAM PRO uses current signature and voltage analysis to provide critical insights.

Customizable reports based on over 4,000 calculated parameters for current and voltage data are used to provide real-time asset optimization.