SAM PRO – Smart Asset Management for Performance and Reliability Optimization

Real-time asset condition monitoring solution for industrial rotating equipment

SAM PRO (Smart Asset Management Performance And Reliability Optimization) is a real-time condition monitoring solution for industrial rotating equipment.

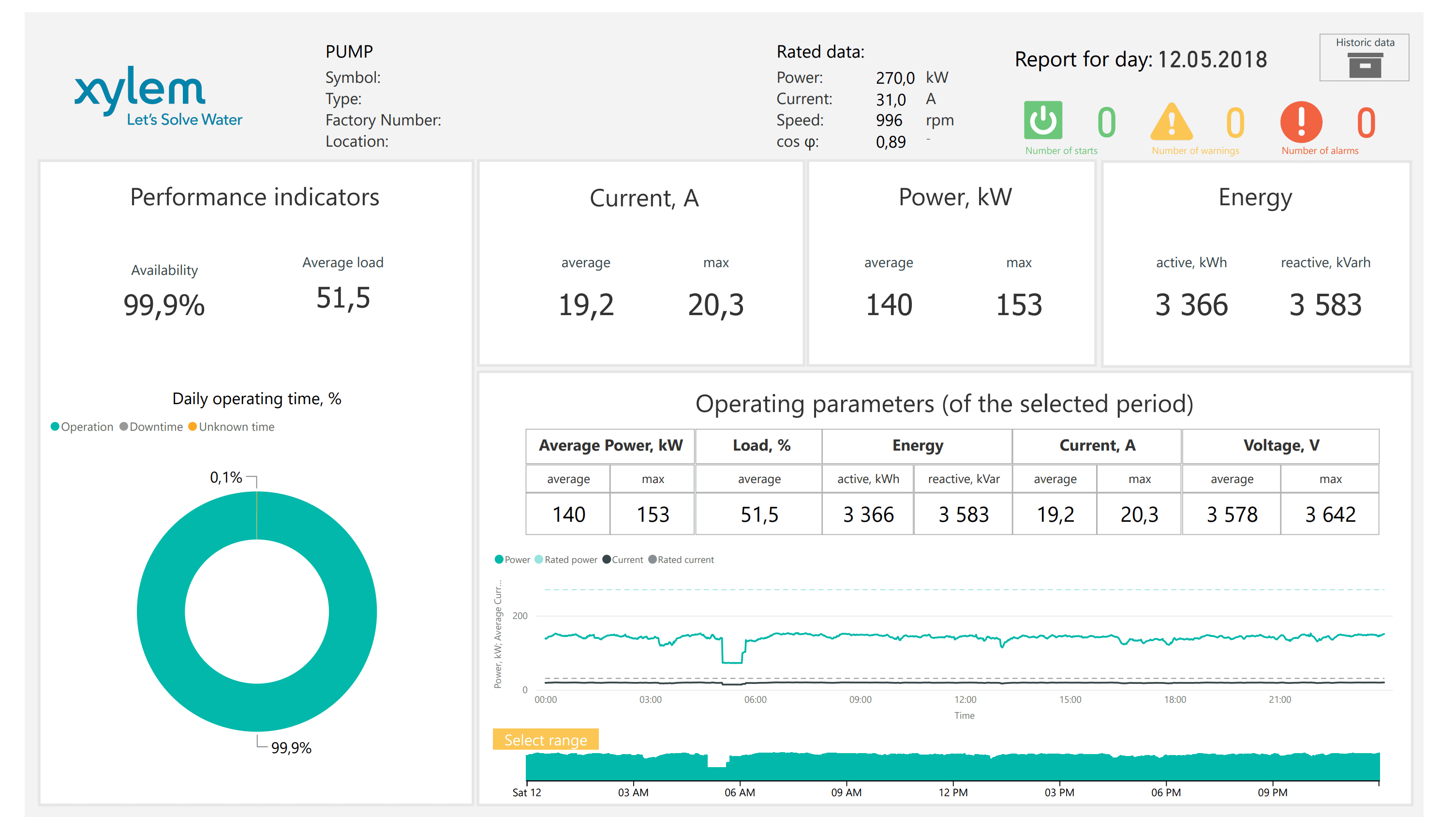

It combines measurements of voltage and current from electric-motor power lines with important parameters, like pressure and temperature, to create actionable insights. Enabled by an algorithm that can detect discrepancies long before they could be flagged by operators or performance indicators, this intelligent software even pinpoints the exact location and element driving the alerts, allowing you to make crucial decisions — earlier.

What does SAM PRO do for you?

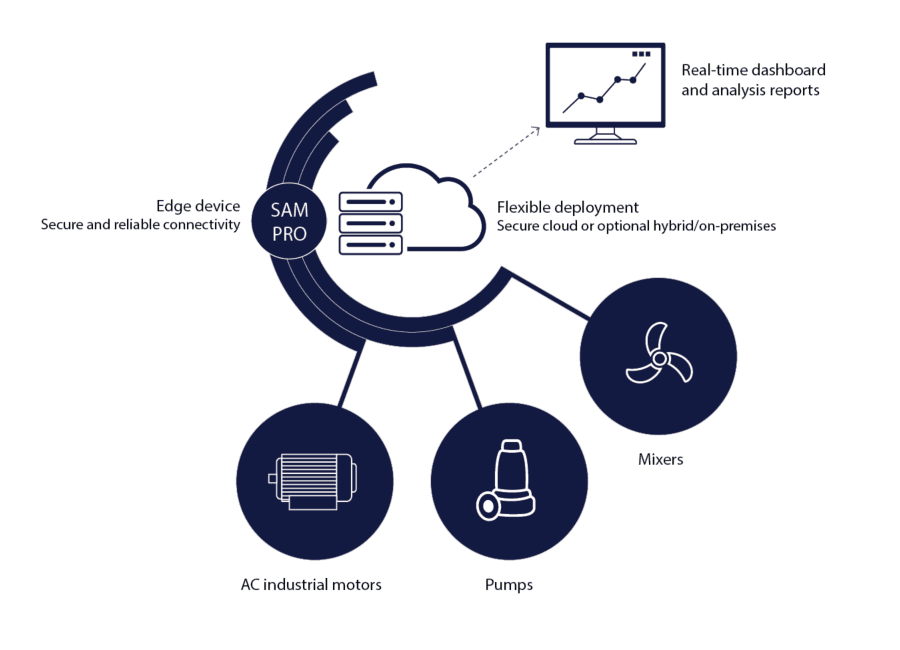

How does SAM PRO work?

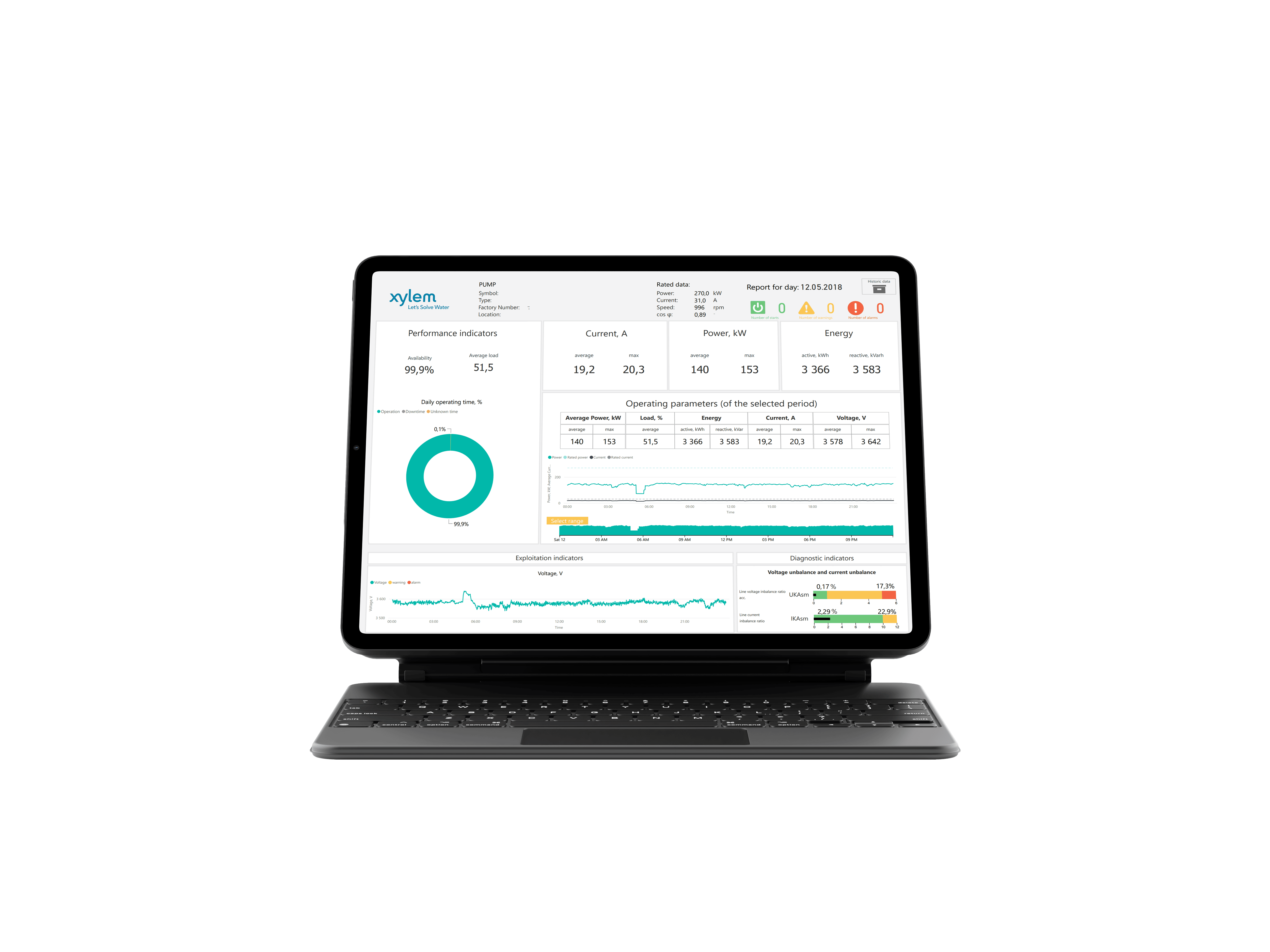

1. Edge devices* capture and process data, such as temperature, pressure and electric parameters of the machine.

2. The devices then transmit the resulting KPIs to the server** (secure cloud or optional hybrid/on-premises).

3. KPIs enable report generation through our real-time dashboard, or the cloud can direct to customer systems such as supervisory control and data acquisition (SCADA) systems, enterprise asset management (EAM) systems or IoT systems.

*Edge refers to a system that brings computation and data storage closer to the sources of data. Edge devices can gather data in real time and apply analytics to provide faster insights and improved response times.

**Authorized users can gain access to the server via a password-protected login, or SAM PRO can be integrated with other data management systems via industrial automation standard protocols or application programming interface (REST API).

Applications

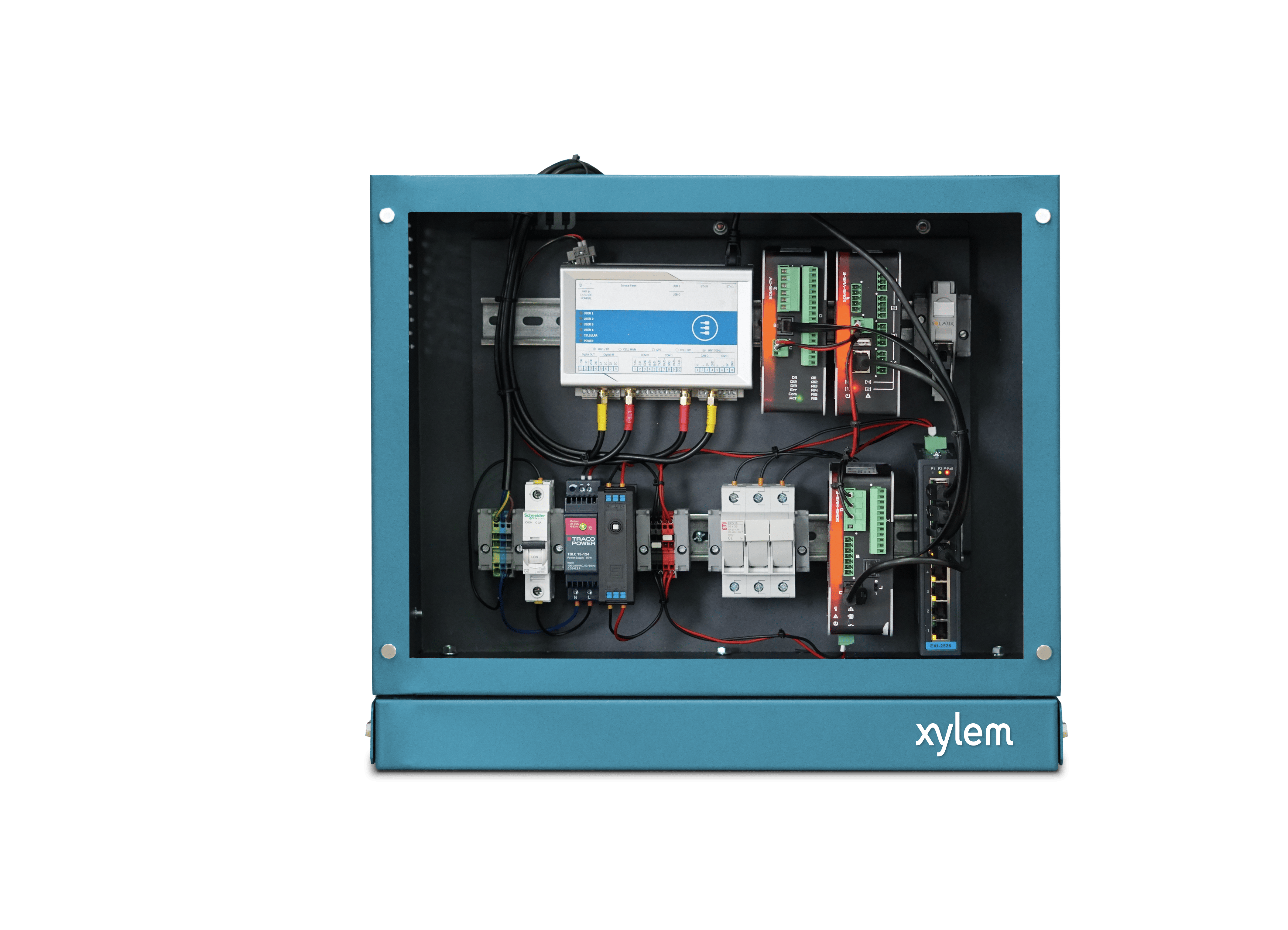

SAM PRO machine-monitoring modules can be installed directly in the machine-motor control panel. If there is no space available, the modules can also be provided in a commissioned, pre-wired micro panel for rapid site deployment.

It can be used with any existing asset, regardless of make, model or age, monitoring and preventing machine failures such as:

Smart condition monitoring with predictive insights prevents unplanned stoppages and allows maintenance to take place at exactly the right time.

This improves your life-cycle cost (LCC) and overall equipment effectiveness (OEE) through:

Smart condition monitoring with predictive insights prevents unplanned stoppages and allows maintenance to take place at exactly the right time.

This improves your life-cycle cost (LCC) and overall equipment effectiveness (OEE) through:

Reduced energy consumption

- Minimize energy use with high-value technical and operational condition information.

- Increase machine efficiency based on power supply disturbance information and patented signature analysis.

- Improve process efficiency by precisely correlating technical machine condition with the process conditions.

Increased lifetime of assets

- Improve total productive maintenance (TPM) through benchmarking and diagnostic insights.

- Limit repair costs and process disruption by diagnosing failures before they happen.

- Streamline maintenance and inspection processes with reliable data viewable on demand, not requiring constant monitoring.

Enhanced productivity

- Increase manufacturing productivity with an operational map informed by highly consistent processed data, derived from multiple sources.

- Reduce downtime through product data management (PDM) and data-driven operations.

- Avoid quality deterioration with built-in machine-learning algorithms.

SAM PRO provides performance insights for both mechanical and electrical systems.

This sophisticated software monitors asset operations, allows for perfectly timed maintenance and predicts future failures to eliminate unplanned stoppages and drastically reduce business risks. The system also collects data that can be used to design the most profitable long-term plan for asset usage,

giving you optimal machine, energy and process efficiency, and better return on the capital invested.

SAM PRO will work with any make or model of asset. For applications where deploying sensors is difficult or inconvenient, such as high-voltage, high-flow and/or low-pressure submersible pumps, SAM PRO uses current signature and voltage analysis to provide critical insights.

Customizable reports based on over 4,000 calculated parameters for current and voltage data are used to provide real-time asset optimization.

SAM PRO is an important part of our full suite of digital solutions, Xylem Vue, that combines smart and connected technologies, intelligent systems and services, and 100+ years of problem-solving expertise. Our digital solutions and services make the lives of operators of water and wastewater infrastructure easier by remotely managing assets, optimizing performance and predicting failures.

Digital transformation starts with Xylem Vue

Digital adoption is no longer an option, it’s an urgent reality to meet the increasing pressures you face. Xylem Vue brings together our full portfolio of digital solutions to solve your most pressing water challenges along your digital journey. Let’s see what’s possible for you.

Discover more at https://xylem.com/XylemVue