Overview

- Flows up to 2200 m3/h

- Heads up to 76 m

- Power ratings 37 - 70 kW

- Discharge connection sizes 150 - 350 mm

- Pump weights 970 - 1320 kg

The Flygt N 3301 medium capacity pump series provides efficient clog-free transportation of clean water, surface water, and wastewater containing solids. It is available with premium efficiency motors and in explosion-proof and warm-liquid versions.

Flygt N 3301 pumps feature the self-cleaning N-impeller in Hard-Iron, grey iron or stainless steel and can be delivered for wet or dry installation (configurations P, S, T, Z).

Non-Clog Pumping for Modern Wastewater

Thanks to Flygt N-technology impellers, Flygt N-pumps deliver sustained high efficiency. They lower your energy bill and reduce unplanned maintenance costs, providing big savings over the long term.

Most solid objects entering the pump will pass through the impeller between the impeller vanes. If an object gets caught on the leading edge of one of the vanes, it will slide along the backswept shape toward the perimeter of the inlet and be guided out through the relief groove.

Due to the mechanical self-cleaning design, non-organic solids are no match for Flygt N-pumps and a sludge concentration up to 8% can easily be pumped.

Robust Impeller Material Options

Flygt N-impellers can be supplied in a variety of materials depending on application requirements. Hardened grey iron impellers are suitable for typical wastewater applications with low amounts of corrosives. For abrasive and corrosive applications, Flygt’s Hard-Iron (60 HRC) demonstrates superior wear resistance. A duplex stainless steel impeller is available for applications requiring a high resistance to corrosion.

The replaceable impeller wear ring is available in both grey iron and Hard-Iron.

Cooling Options for Tough Environments

Flygt N 3301 pumps typically come with an advanced closed-loop cooling system suitable for dry, partially submerged, and fully submerged applications. Flygt’s system uses a precise mixture of pure water and a proprietary polypropylene glycol formulation. It has excellent heat transfer and corrosion resistance properties and is freeze-proof down to -45°C.

For applications where liquid temperatures exceed 40°C, an external cooling system is available to maintain pump performance.

Flexible, Modular Design

With a modular design and a range of options, Flygt N-technology pumps can be tailored to meet the needs of your specific applications.

- Self-cleaning N-impeller in hardened grey iron, Hard-Iron or duplex stainless steel

- Replaceable wear ring in grey iron or Hard-Iron

- Short shaft overhang, reducing shaft deflection and increasing seal and bearing life

- Motor designed for submersible use, with Class H insulation and heat losses concentrated around the stator core for improved cooling properties. Option to upgrade to IE3 comparable premium efficiency motor

- Cooling via internal closed-loop cooling, direct cooling or external cooling

- Flygt Plug-in seal with Active Seal system for greater sealing reliability and zero leakage to motor. Available in Tungsten carbide (WCCR) or Silicone carbide (SiC) depending on pumped media

- Flygt Spin-out seal protection option to prevent seal wear caused by abrasive particles

- Inspection chamber and built-in sensor for early leakage detection

- SUBCAB® motor cable specially developed for submersible use

Installation Configurations

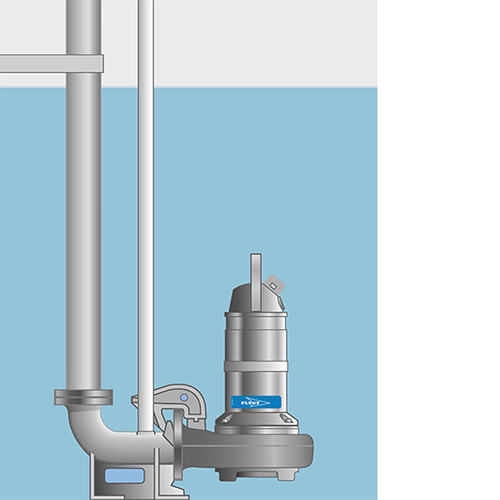

Wet Pit (P)

Semi permanent, submersible pump installation. Wet pit arrangement with the pump installed on twin guide bars with automatic connection to the discharge pipe.

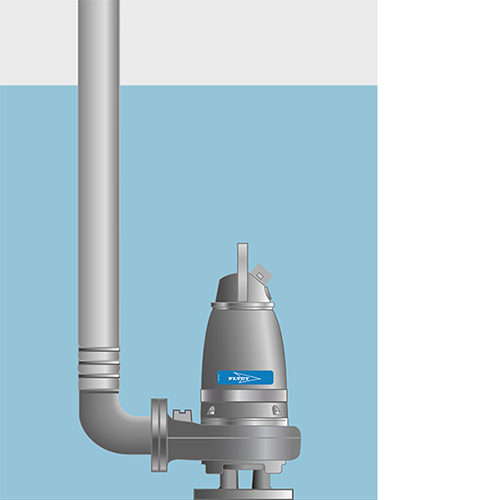

Portable (S)

Portable, submersible pump installation. Portable pump with hose coupling or flange for connection to the discharge pipe.

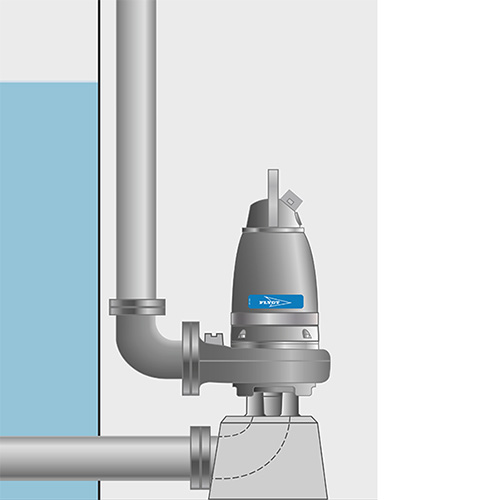

Dry Installation Vertical (T)

Vertical, permanent, dry pump installation. The submersible pump is installed in a dry pit, with flange connection to suction and discharge piping.

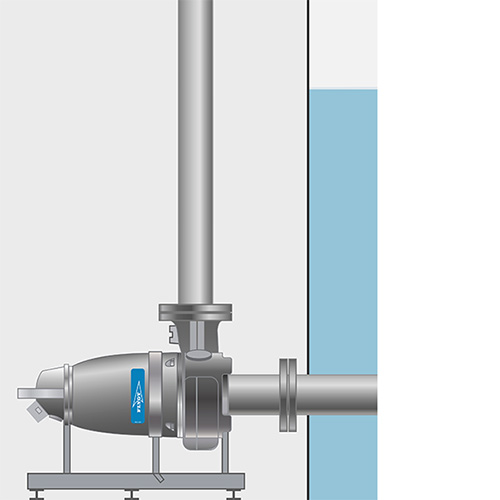

Dry Installation Horizontal (Z)

Horizontal, permanent, dry pump installation. The submersible pump is installed in a dry pit, with flange connection to suction and discharge piping.