Overview

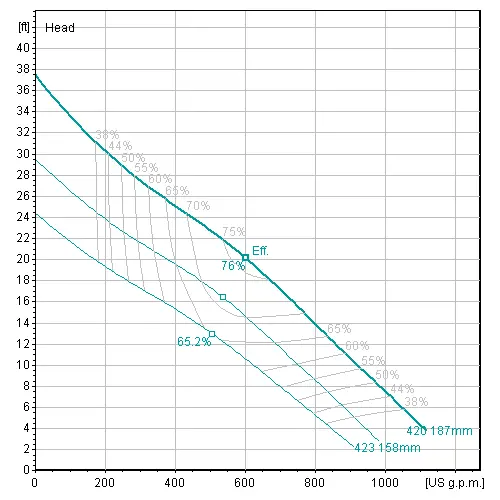

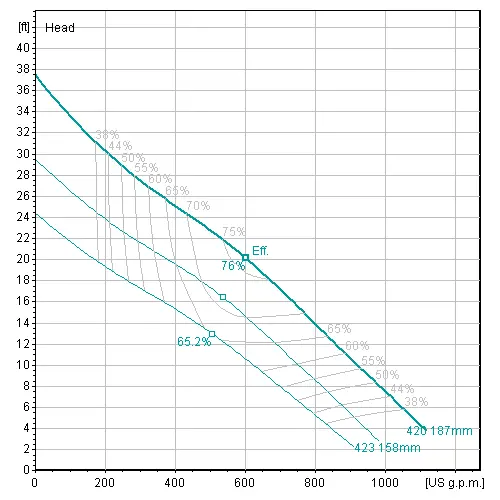

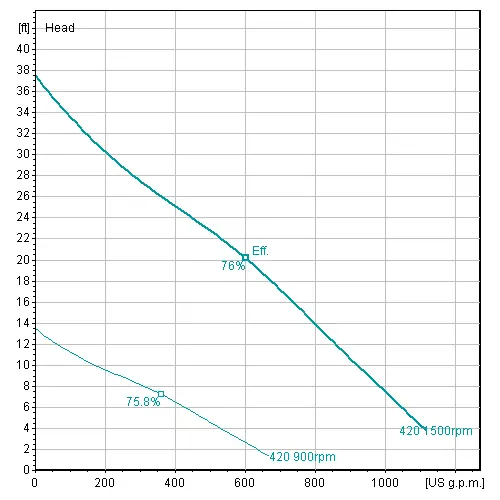

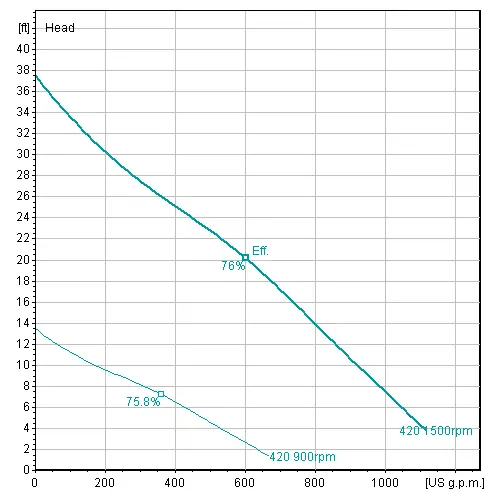

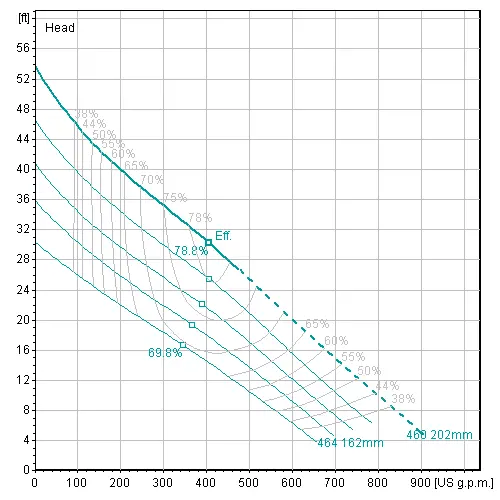

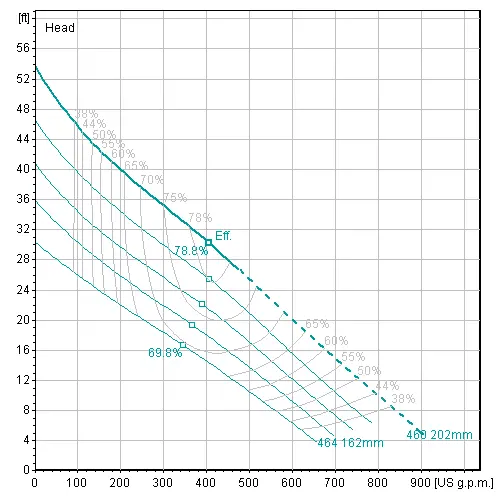

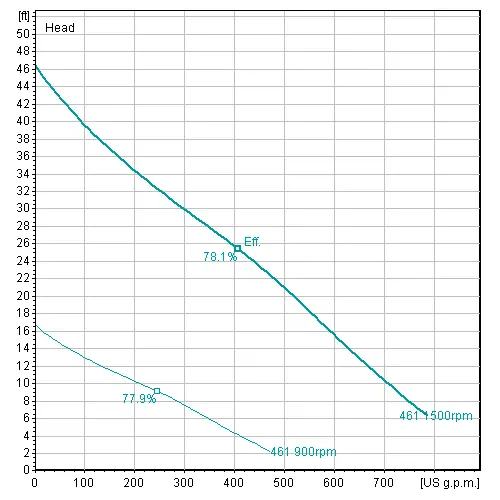

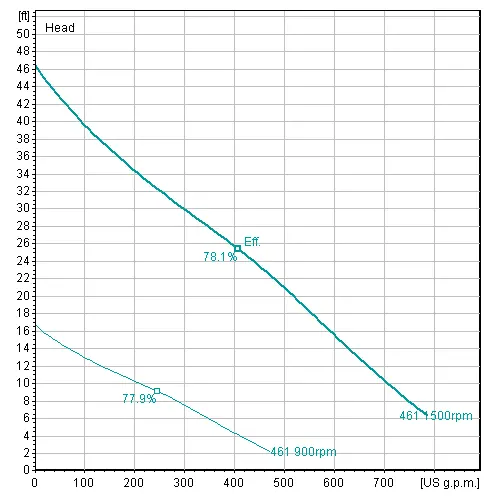

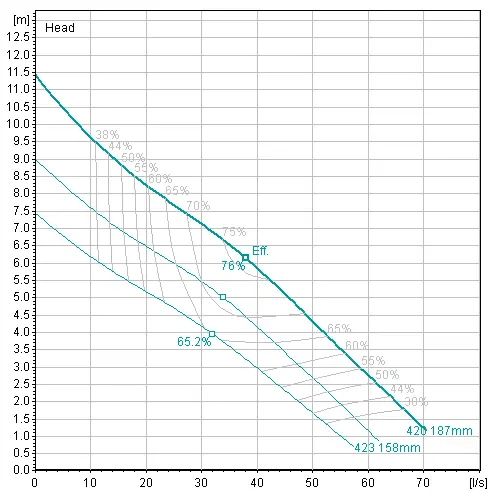

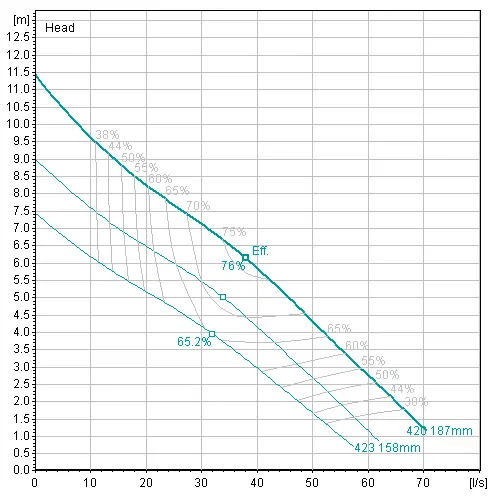

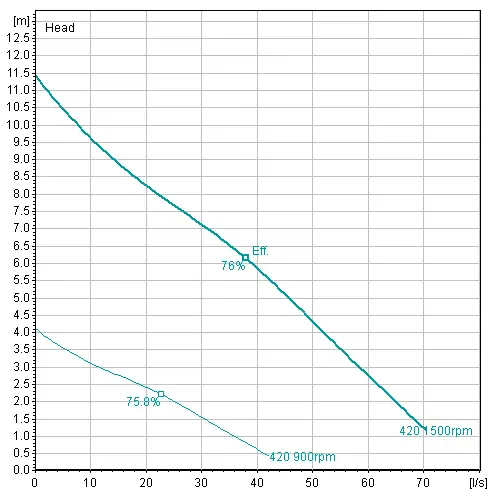

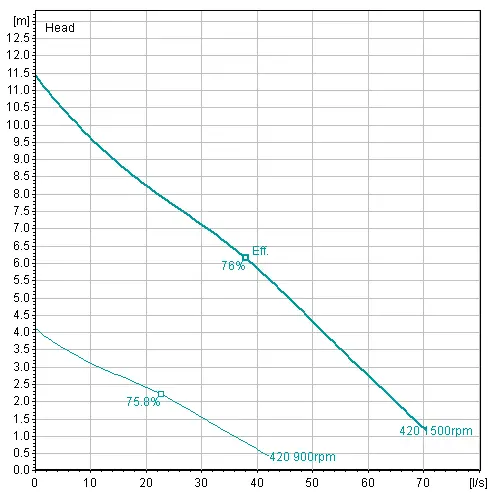

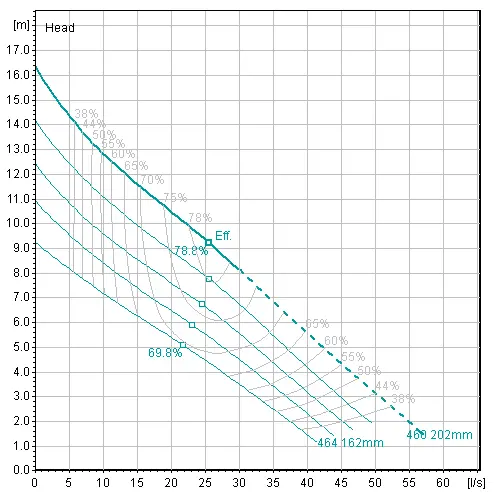

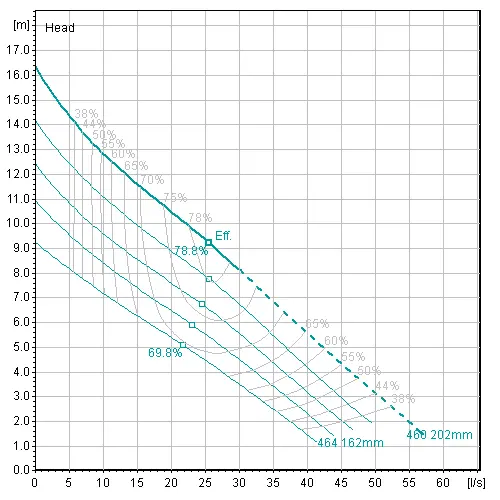

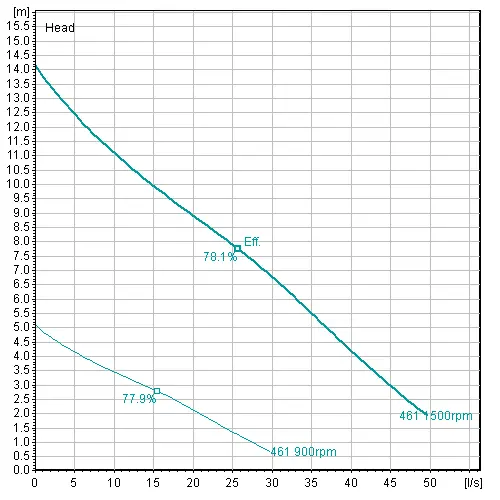

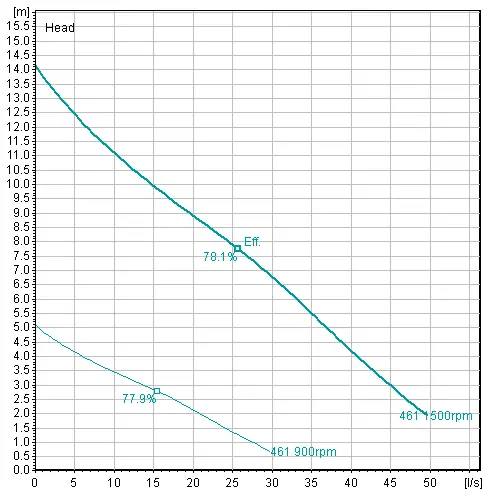

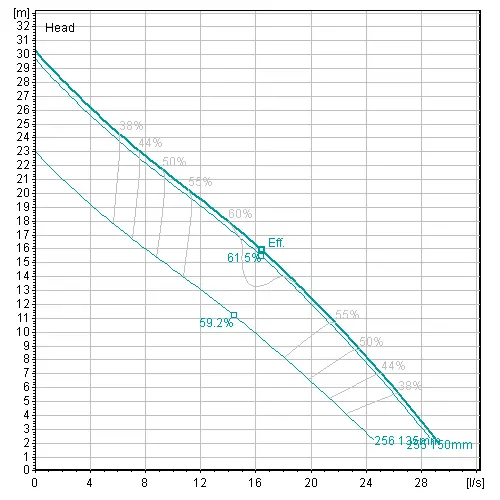

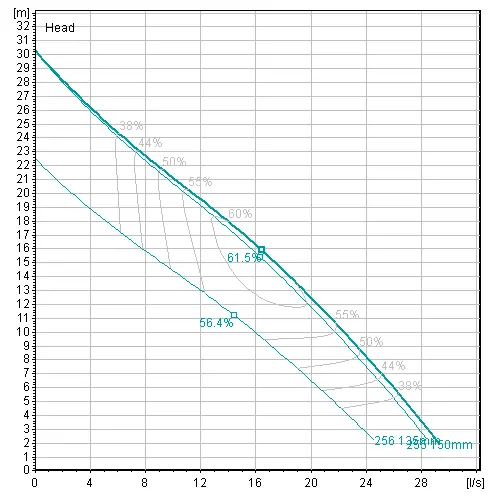

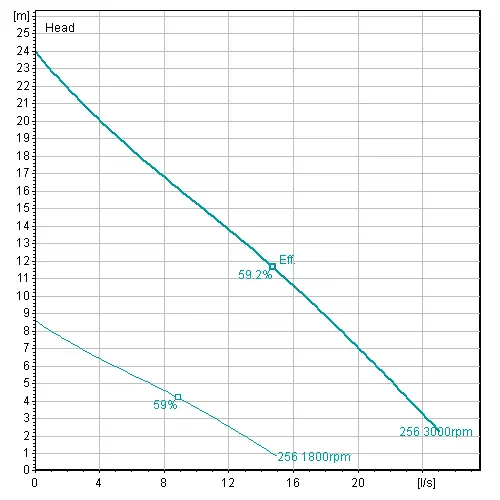

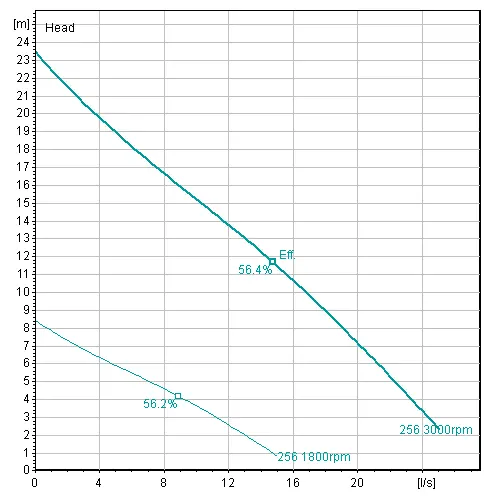

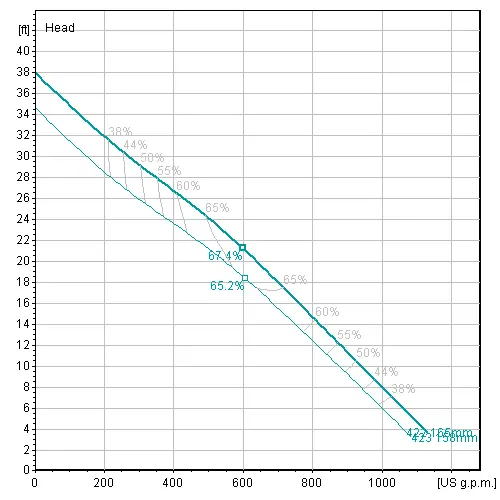

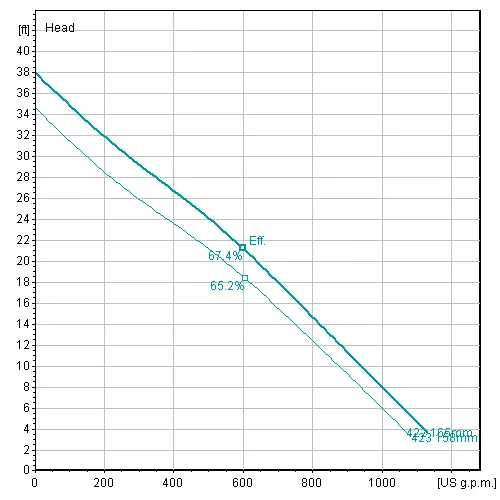

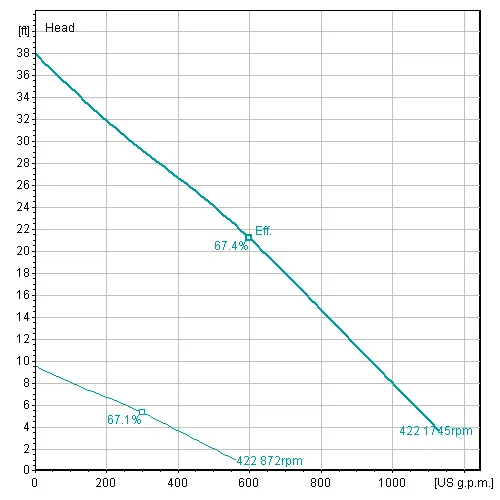

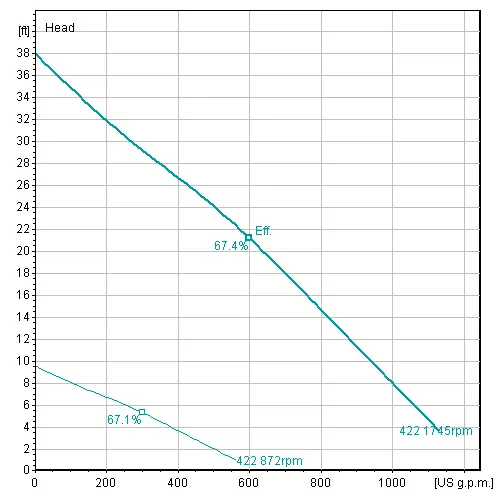

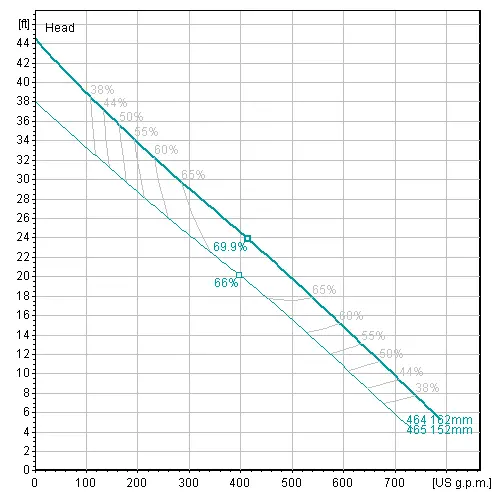

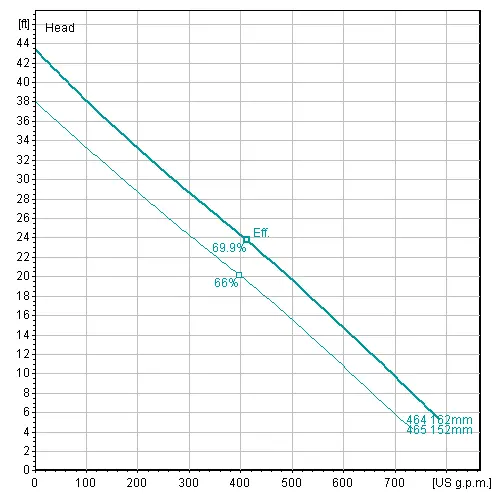

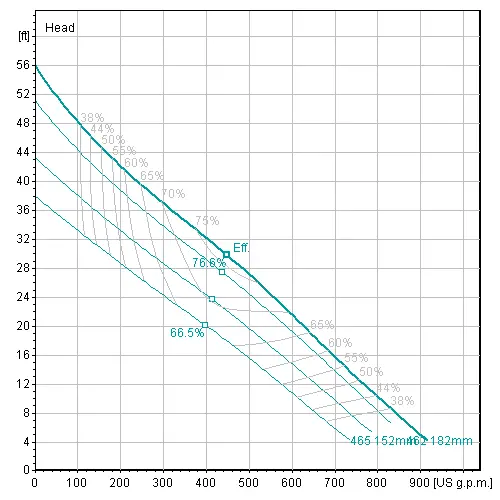

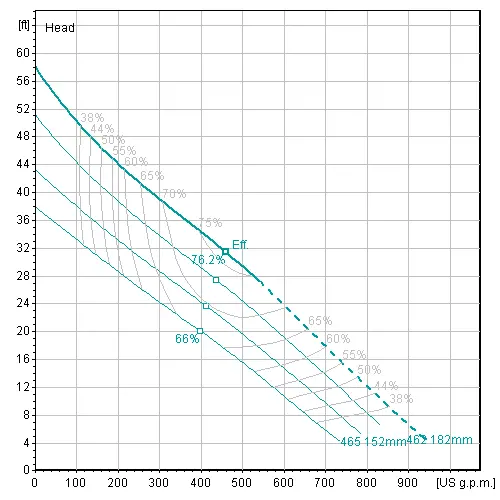

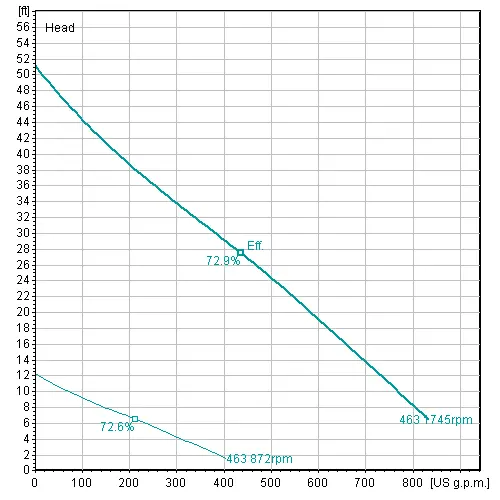

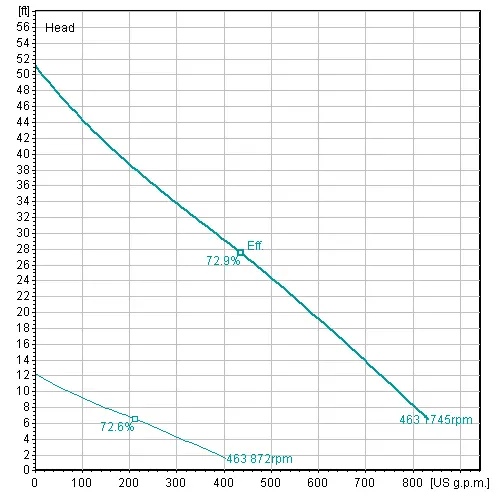

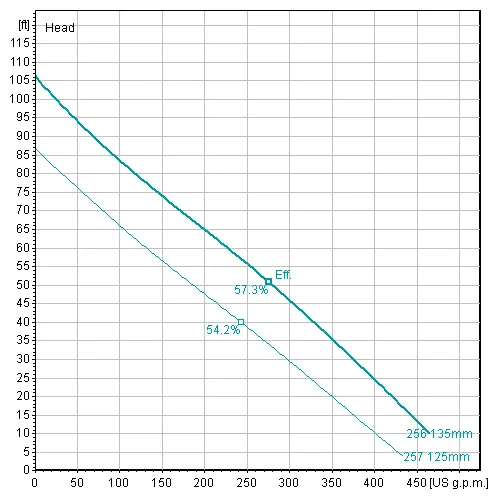

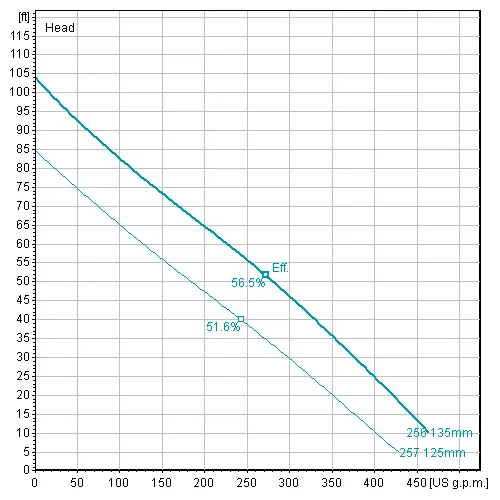

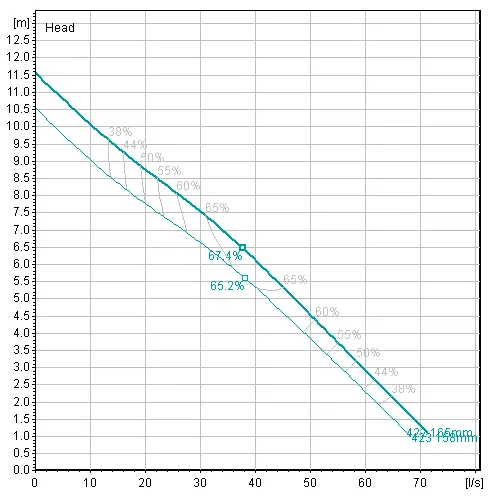

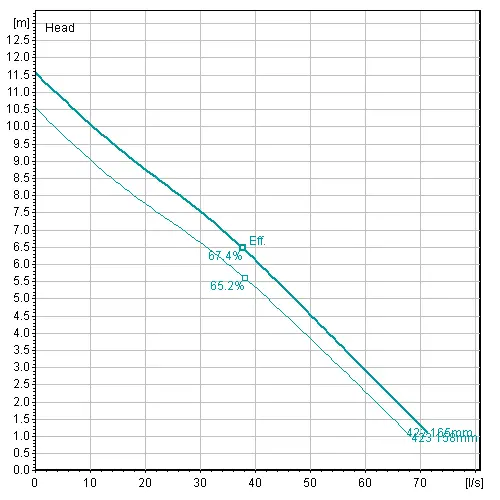

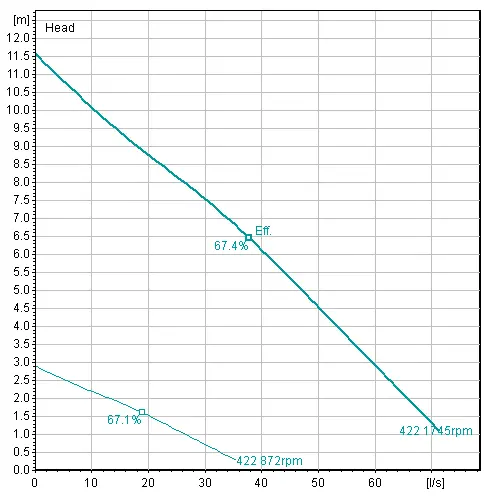

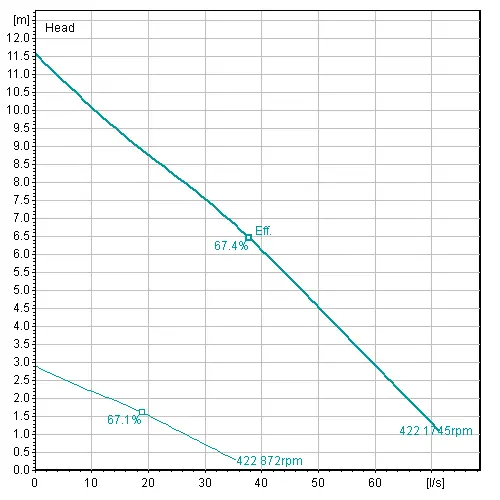

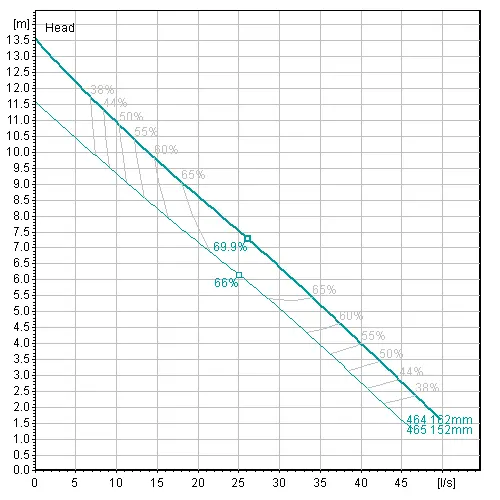

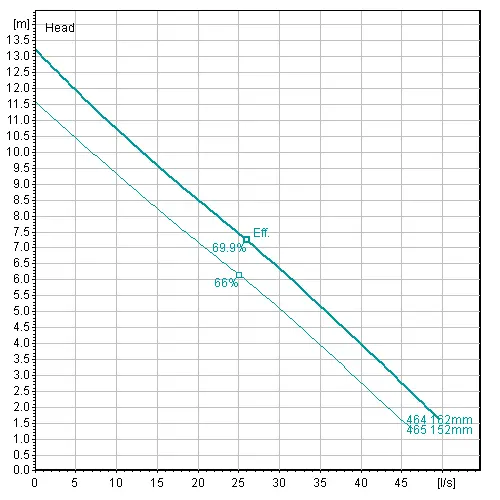

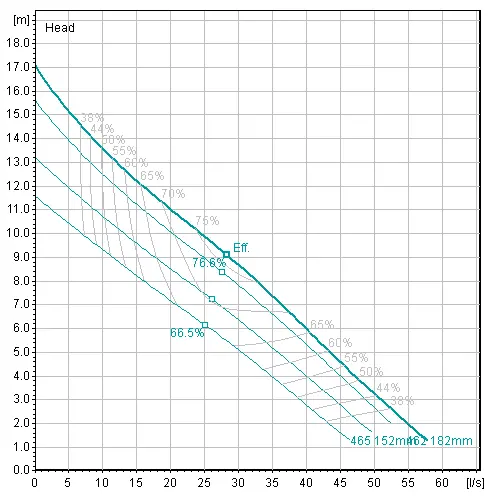

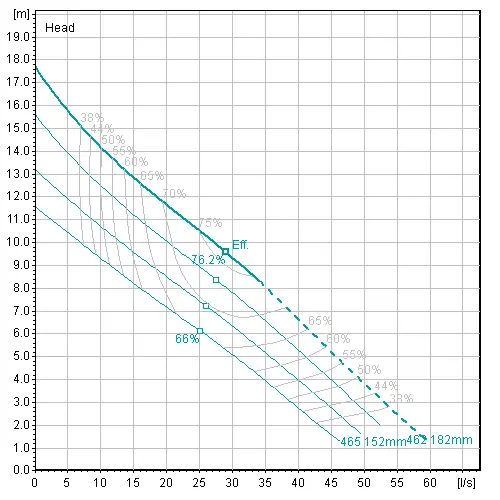

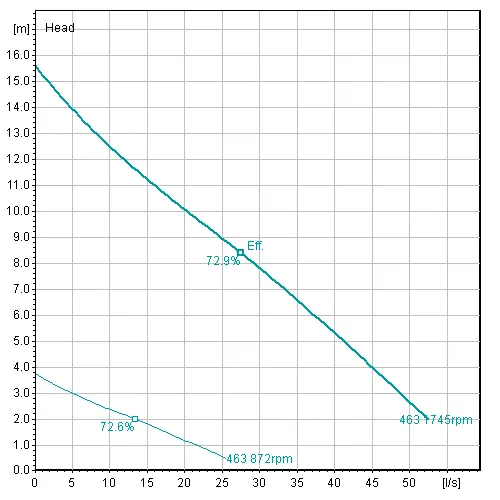

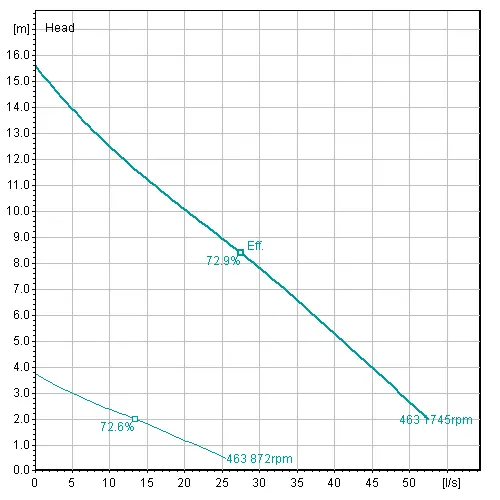

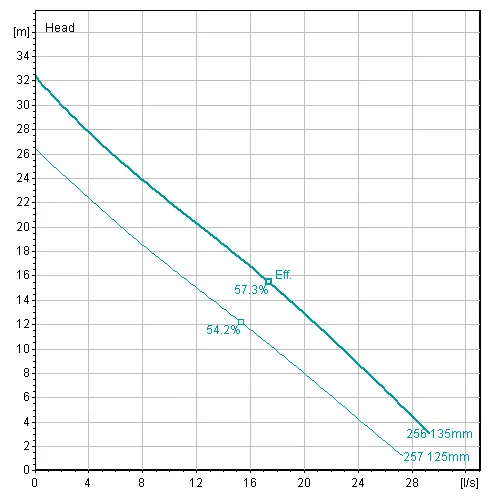

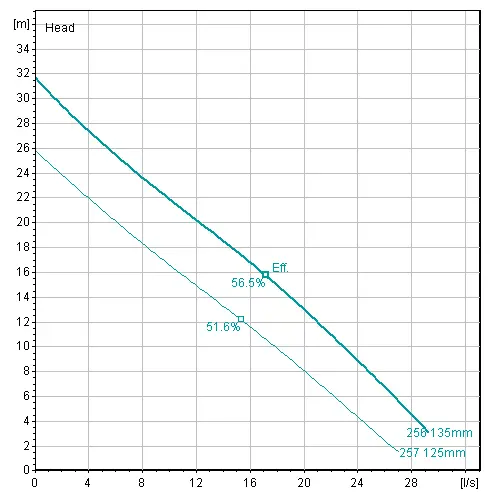

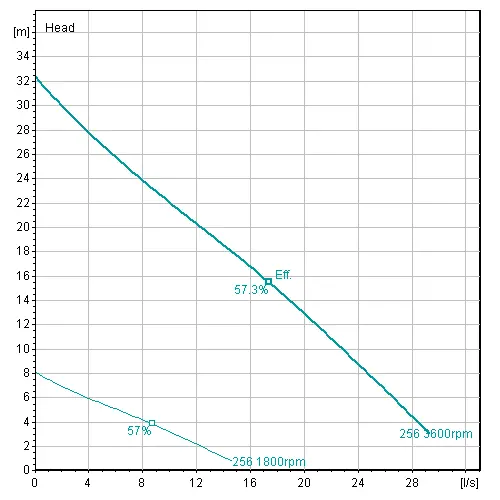

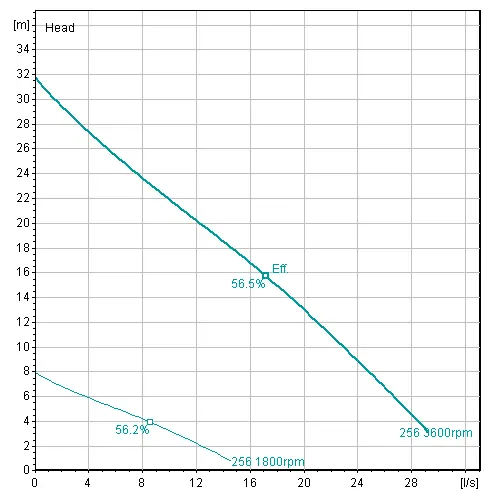

- Flows up to 245 m3/h

- Heads up to 29 m

- Power ratings 3.1 - 4.2 kW

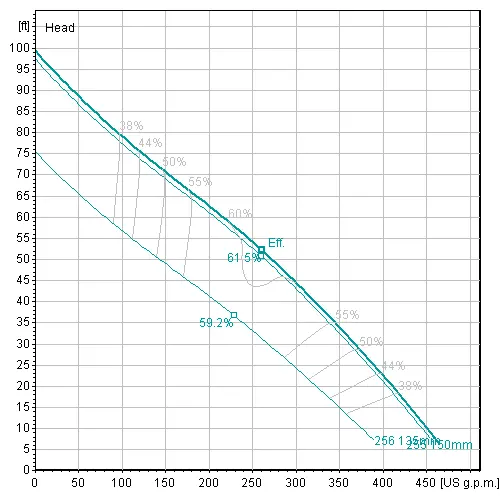

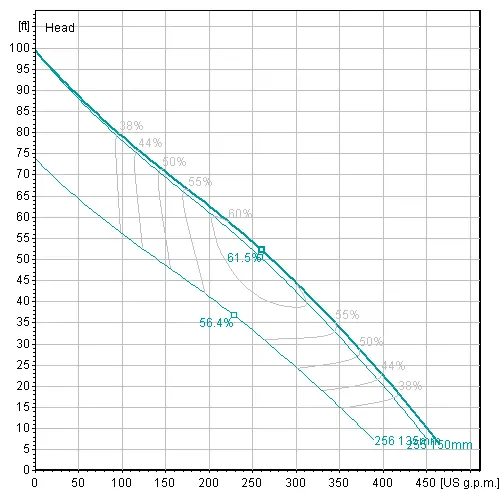

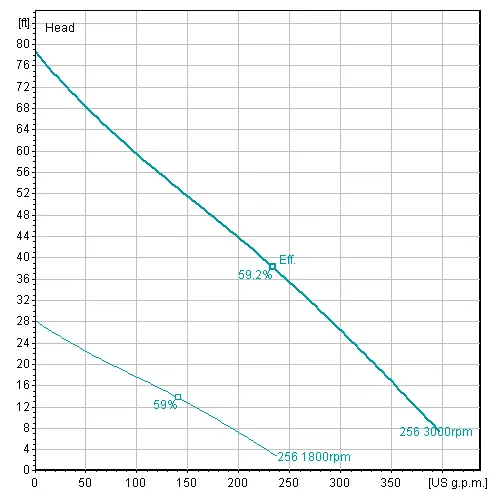

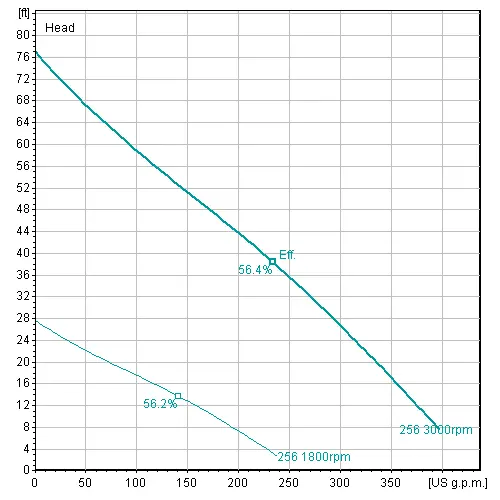

- Discharge connection sizes 80 - 150 mm

- Pump weights 105 - 117 kg

The Flygt N 3102 low-to-medium flow wastewater pump series, with Adaptive N® hydraulic technology, is available in standard and explosion-proof versions and can be customized to your requirements with impeller material options of Hard-Iron or grey iron to ensure best-in-class media handling capabilities.

For added flexibility, the Flygt N 3102 series can be configured for wet or dry, vertical or horizontal installation, including column pipe installation (configurations L, P, S, T, Z, X).

Clog-Free Adaptive N Impeller for Small Wastewater Pumps

Flygt N-pumps provide continuous trouble-free pumping for the toughest wastewater challenges. Our small Flygt N-technology pump range features the Adaptive N impeller for sustained high efficiency and smooth operation, even when pumping fluids high in solids and fibrous content. Thanks to the self-cleaning impeller design, Flygt N-pumps lower your energy bill and reduce unplanned maintenance costs. That adds up to total peace of mind – and big savings over the long term.

Most solid objects entering the pump will pass through the impeller between the impeller vanes. If an object gets caught on the leading edge of one of the vanes, it will slide along the backswept shape towards the perimeter of the inlet and be guided out through the relief groove.

When larger objects enter the pump, the Adaptive N technology allows the impeller to lift and let the objects through.

Due to the mechanical self-cleaning design, a sludge concentration up to 8% can easily be pumped.

Impeller Materials to Meet Application Needs

The Flygt Adaptive N impeller is available in two material options to meet the challenges of today’s wastewater media.

Hardened grey iron impellers are suitable for typical wastewater applications, while our Hard-Iron (60 HRC) impeller provides superior wear resistance for abrasive and corrosive applications.

The replaceable wear ring is also available in either grey iron or Hard-Iron to meet different operating conditions.

High-Performing Design for Lower Lifecycle Costs

The Flygt N 3102 series has been designed to address common challenges of small wastewater pumps: clogging, overheating, and a rapid loss of pumping efficiency. It features:

- Adaptive N impeller for non-clog performance and sustained high efficiency.

- Short shaft overhang, reducing shaft deflection and increasing seal and bearing life.

- Motor designed for submersible use, with heat losses concentrated around the stator core for improved cooling properties.

- Double mechanical seal system consisting of two sets of mechanical shaft seals that work independently to provide double security. Available in Tungsten carbide (WCCR) or Silicone carbide (SiC) depending on pumped media.

- Griploc system that secures the seals to the shaft with no rubber friction, no grub screws and no shaft damage.

- SUBCAB® motor cable specially developed for submersible use.

Installation Configurations

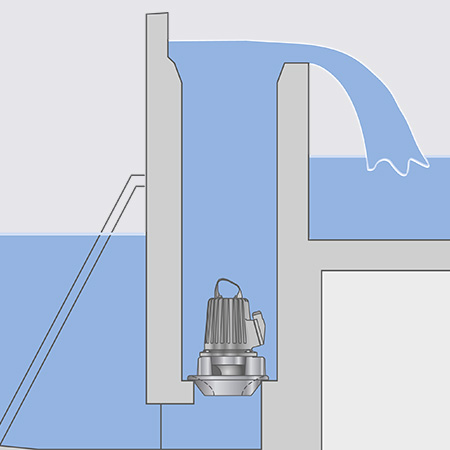

Column Pipe (L)

Semi-permanent, wet well column pipe installation. The well is divided into suction and discharge portions.

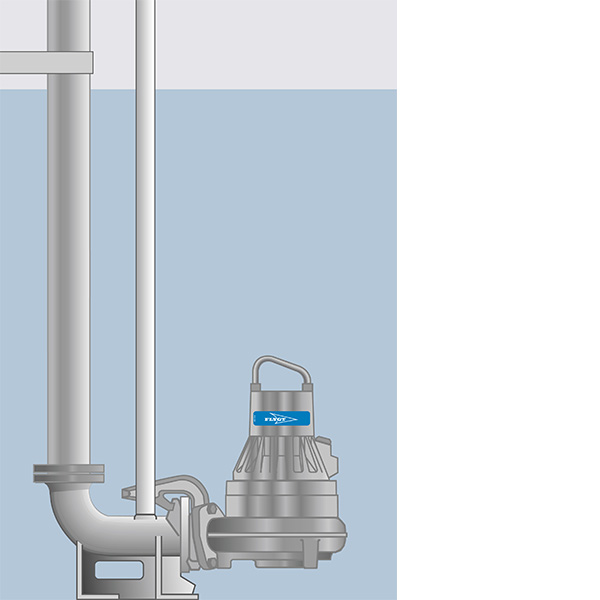

Wet Pit (P)

Semi-permanent, submersible pump installation. Wet pit arrangement with the pump installed on twin guide bars with automatic connection to the discharge pipe.

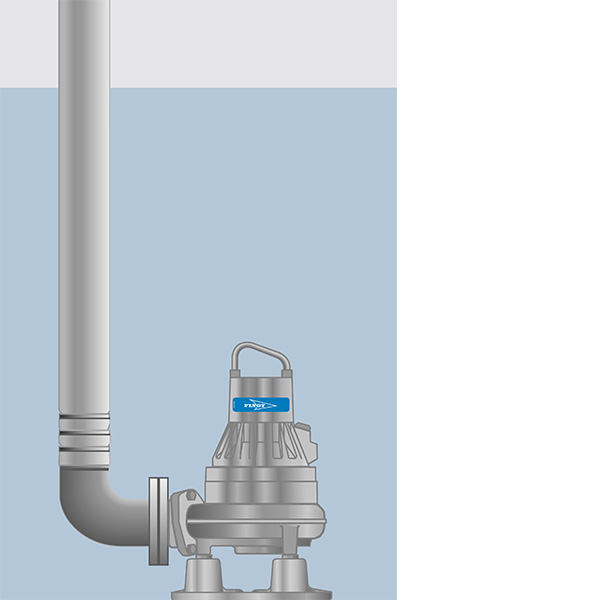

Portable (S)

Portable, submersible pump installation. Portable pump with hose coupling or flange for connection to the discharge pipe.

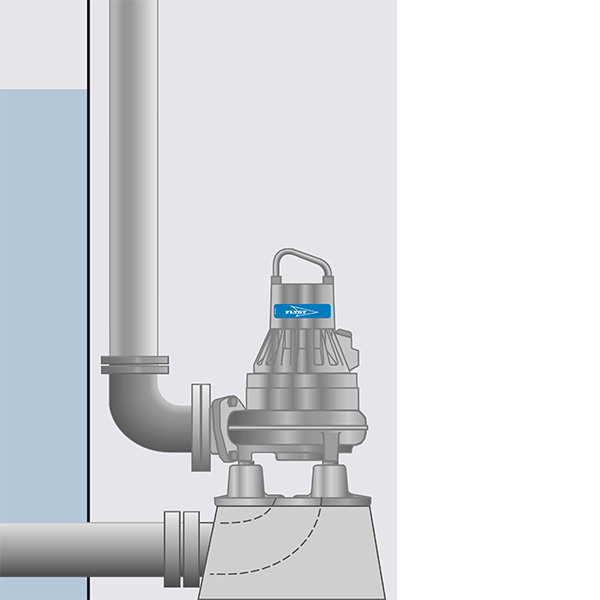

Dry Installation Vertical (T)

Vertical, permanent, dry pump installation. The submersible pump is installed in a dry pit, with flange connection to suction and discharge piping.

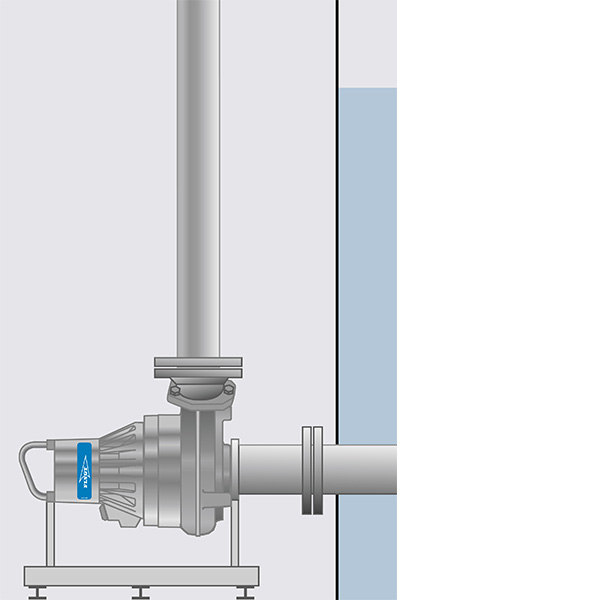

Dry Installation Horizontal (Z)

Horizontal, permanent, dry pump installation. The submersible pump is installed in a dry pit, with flange connection to suction and discharge piping.

Drilled Flange (X)

The pump has no pre-determined mechanical connection. The outlet flange is drilled.